News

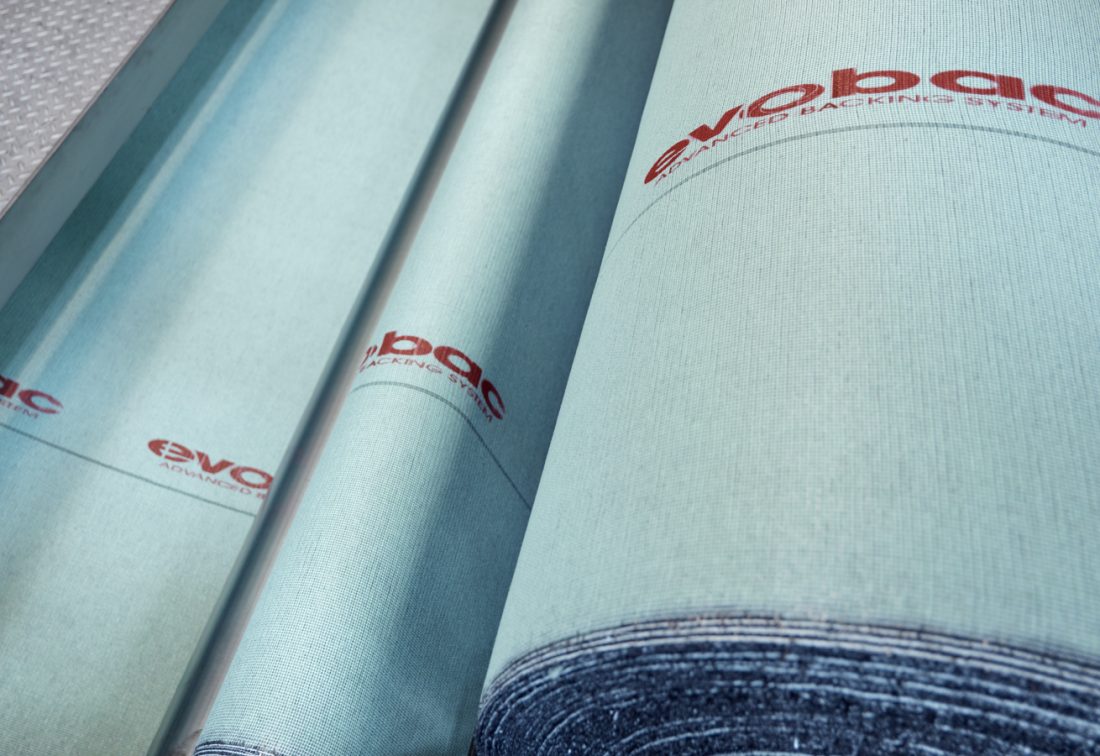

Evobac Sustainable Carpet Backing

There are many ways in which we at Newhey differentiate ourselves from other hospitality carpet manufacturers. We are huge supporters of “Made in Britain”. We work in partnership with experienced local suppliers. We insist on the highest quality wool rich yarns. We produce high quality carpets that are exceptional value for money. We invest heavily in design and new technology.

Now stop right there if you’re about to unscrew the cap off a bottle of spring water. Put the bottle down and read on.

One of the things that our clients are increasingly conscious of is their impact on the environment. Not just theirs, but that of their suppliers, too. Sustainability is now a prerequisite and when appointing a partner for many interior designers, architects, specifiers and developers. If you aren’t a sustainable supplier, you can whistle.

Introducing Evobac

Plastic waste is a huge global problem. It is finding its way into our seas and landfill in ever increasing quantities. Its effect on marine animals is particularly distressing and entirely avoidable with responsible recycling.

Newhey has invested considerable time, money, resources and faith in a revolutionary carpet secondary backing system that utilizes Evobac technology.

Click the link below to watch a short video that shows you the revolutionary secondary backing line in motion

Evobac is made from 100% recycled PET post-consumer plastic – basically, discarded plastic bottles that could have a detrimental effect on our oceans and ecosystems. Evobac rescues and makes great use of them.

To give you an idea, specifying just one square metre of Newhey carpet, with evobac, prevents at least eight from going to landfill or entering our oceans. In one year of normal production that equates to 20 tonnes. That’s a lot of plastic bottles.

Evobac is hot stuff

Not only is Evobac incredibly sustainable, it also delivers another benefit. Most traditional carpet backing systems are what we refer to in the trade as ‘wet’ backed, they apply a glue that takes time and certain conditions to set properly.

Evobac is entirely different. It is the only system that is applied ‘hot’ and dried instantly. The benefits of this are twofold. Not only is the adhesive of the backing superior and longer lasting, it dries more quickly which reduces production time.

It’s basically a win, win, win, win win… production process.

Stock Collections

Stock Collections Express Collection

Express Collection Bespoke Design Service

Bespoke Design Service Area Rugs

Area Rugs Heritage

Heritage Local Supply

Local Supply News

News Meet our Team

Meet our Team